SMART Compact Orbital Welding Power Source ORBITRON-7000 INDUSTRY 4.0

Features :

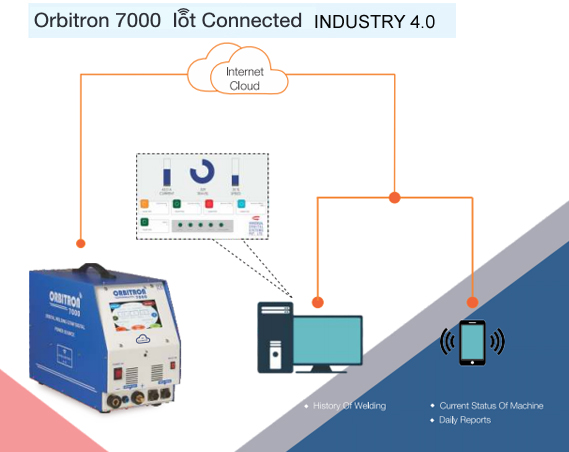

Smart Industry 4.0 ready power source with IOT.

Smart Industry 4.0 ready power source with IOT.

IOT connected power source by which your can communicate the machine and get Daily Reports for Orbitron 7000.

IOT connected power source by which your can communicate the machine and get Daily Reports for Orbitron 7000.

You can see machine status on Cloud or using Android App for Orbitron 7000.

You can see machine status on Cloud or using Android App for Orbitron 7000.

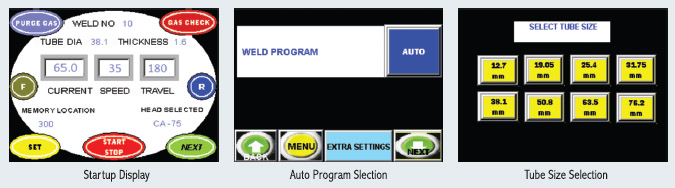

Auto programming mode generates welding parameters data Automatically.

Auto programming mode generates welding parameters data Automatically.

Stores 600 programs 200 auto and 400 Manual programs.

Stores 600 programs 200 auto and 400 Manual programs.

Manual programs can be stored with Tags

Manual programs can be stored with Tags

Compact, Rugged, Noise proof design, Weighing only 15 Kg., easy carrying for site and runs on generators also.

Compact, Rugged, Noise proof design, Weighing only 15 Kg., easy carrying for site and runs on generators also.

A simple design, user friendly

A simple design, user friendly

Segment wise programming with Positional Reference.

Segment wise programming with Positional Reference.

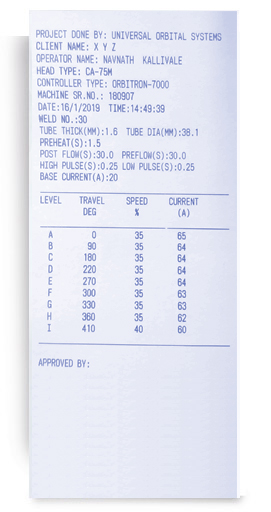

In built Weld Data Logger with USB port & Pen Drive.

In built Weld Data Logger with USB port & Pen Drive.

Auto fault detection detects "Arc Fault", "Rotor Jam", "Earth Fault" "Gas Fault" & and user guidance to fix the fault.

Auto fault detection detects "Arc Fault", "Rotor Jam", "Earth Fault" "Gas Fault" & and user guidance to fix the fault.

Suitable for all UNIVERSAL Weld Heads including Tube to Tube and Tube to Tube Sheet.

Suitable for all UNIVERSAL Weld Heads including Tube to Tube and Tube to Tube Sheet.

Password protected key functions for User levels.

Password protected key functions for User levels.

Such as welder, Supervisor, Admin.

Such as welder, Supervisor, Admin.

Auto tacking facility.

Auto tacking facility.

Specially tuned GTAW Power Source with highly Stable current for Orbital Welding.

Specially tuned GTAW Power Source with highly Stable current for Orbital Welding.

Separate compact Water cooling unit for weld Head Cooling.

Separate compact Water cooling unit for weld Head Cooling.

If Machine is offline, data is stored in machine and can be accessed later

If Machine is offline, data is stored in machine and can be accessed later

Features :

Smart Industry 4.0 ready power source with IOT.

Smart Industry 4.0 ready power source with IOT. IOT connected power source by which your can communicate the machine and get Daily Reports for Orbitron 7000.

IOT connected power source by which your can communicate the machine and get Daily Reports for Orbitron 7000. You can see machine status on Cloud or using Android App for Orbitron 7000.

You can see machine status on Cloud or using Android App for Orbitron 7000. Auto programming mode generates welding parameters data Automatically.

Auto programming mode generates welding parameters data Automatically. Stores 600 programs 200 auto and 400 Manual programs.

Stores 600 programs 200 auto and 400 Manual programs. Manual programs can be stored with Tags

Manual programs can be stored with Tags Compact, Rugged, Noise proof design, Weighing only 15 Kg., easy carrying for site and runs on generators also.

Compact, Rugged, Noise proof design, Weighing only 15 Kg., easy carrying for site and runs on generators also. A simple design, user friendly

A simple design, user friendly Segment wise programming with Positional Reference.

Segment wise programming with Positional Reference. In built Weld Data Logger with USB port & Pen Drive.

In built Weld Data Logger with USB port & Pen Drive. Auto fault detection detects "Arc Fault", "Rotor Jam", "Earth Fault" "Gas Fault" & and user guidance to fix the fault.

Auto fault detection detects "Arc Fault", "Rotor Jam", "Earth Fault" "Gas Fault" & and user guidance to fix the fault. Suitable for all UNIVERSAL Weld Heads including Tube to Tube and Tube to Tube Sheet.

Suitable for all UNIVERSAL Weld Heads including Tube to Tube and Tube to Tube Sheet. Password protected key functions for User levels.

Password protected key functions for User levels. Such as welder, Supervisor, Admin.

Such as welder, Supervisor, Admin. Auto tacking facility.

Auto tacking facility. Specially tuned GTAW Power Source with highly Stable current for Orbital Welding.

Specially tuned GTAW Power Source with highly Stable current for Orbital Welding. Separate compact Water cooling unit for weld Head Cooling.

Separate compact Water cooling unit for weld Head Cooling. If Machine is offline, data is stored in machine and can be accessed later

If Machine is offline, data is stored in machine and can be accessed later

Print View

ORBITRON 7000/6000 :

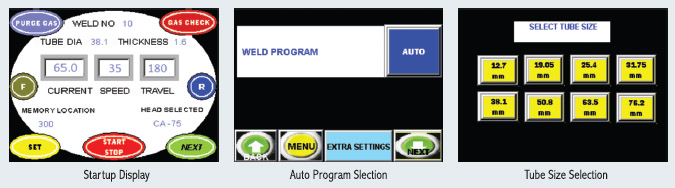

Auto Programming

New auto program generates auto weld procedures

Need to enter tube O.D.and thickness and weld head type

Auto Programming

New auto program generates auto weld procedures

Need to enter tube O.D.and thickness and weld head type

Specifications :

Application |

For use with all UNIVERSAL weld head, Welding Lathe, SPM |

Function controlled |

Weld current / pulse, Weld head rotation, Gas solenoid |

Line Power |

230VAC + -15% 50Hz Single Phase, 15 A, 4KVA |

Motor Control |

24VDC, 1A |

No. of Weld program can be stored |

200 program in AUTO mode 400 program in MANUAL mode |

Weld data Logger Reading storing Capacity |

3000 |

Data recording / Printout |

Operator name, weld ID number, O.D. Wall thickness Date, Time, Weld head model, Project, Drawing Number, Programmed Prameters |

Dimensions |

(L)510 (H)390 (W)220 (L)510 (H)350 (W)240 |

Operating Temperature |

-18 c to 50 c |

Output Current |

10A To 160A |

Pulse Rate |

0.2 To 100 Pulse / Sec |

Open ARC Voltage |

75 VDC |

Weight |

15 kg |

Water Cooling Unit (WT4) :

Capacity |

4 Ltr. |

Dimension (mm) |

L(350) H(165) W(150) |

Weight (kg) |

4 kg |

| Demo Videos : |

Water cooling unit

Printer

Carrying case